HSJ-65 Vacuum Design Corrugated Pipe Machine

HSJ-65 Corrugated Pipe Making Machine

For Washing Machine used corruagted pipe, with socket design

Part A is hollow tube extrusion part and shaping part.

Part B is big diameter pipe twisted and forming part.

It adopts two sets of single-screw extruders to ensure high-speed and high-quality extruding; Unique design of composite die-head and forming by spiral rotation ensure high efficiency and quality; Advanced PLC Control system makes operation very convenient and operation very efficient; Special pipe fittings are adopted and connection is very convenient.

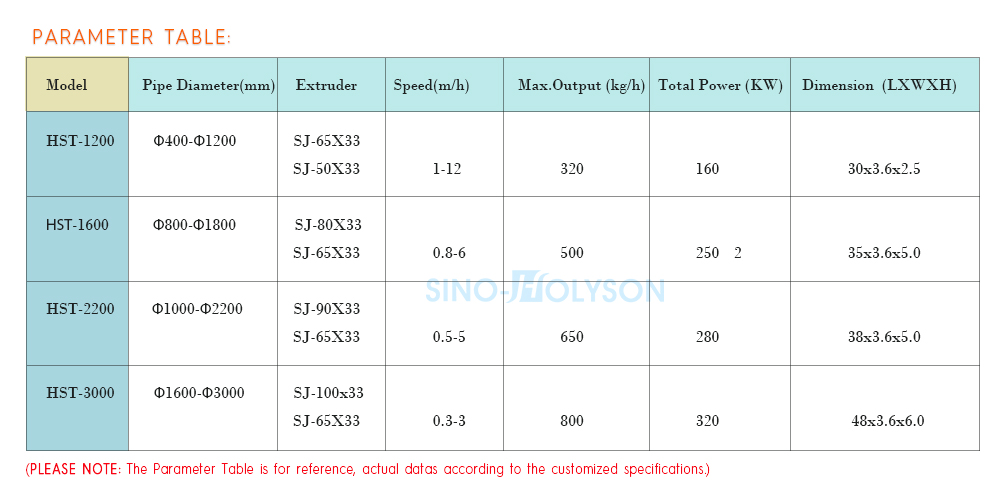

LARGE DIAMETER PIPE EXTRUSION FLOW CHART:

Raw material + Master Batches -- Mixing -- Vacuum Feeding -- Material Dryer -- Single Screw Extruder -- Co-extrusion Mould -- Calibrator - - Spray Vacuum Calibration Tank -- Spray Cooling Water Tank -- Belt Haul-Off -- Single Screw Glue Extruder -- Winder -- Winding Roller Forming -- Water Cooler -- Cutter -- Pipe Rack - - Finished Product Inspecting & Packing

ADVANTAGES OF LARGE DIAMETER PIPE:

HDPE Large Diameter Pipe has been recognized as a substitute for cement pipes and cast iron pipes since it possesses many particular advantages.HDPE large diameter pipes have big market potentiality.

1. This kind of pipes has many extremely excellent characteristics,such as corrosion resistant,light and easy to fix,long life -span(50 years),etc.It can suitable pipes made of high energy consumption material(cement,cast iron,porcelain and ceramics,etc).It is widely used for sewer in super high way municipal construction,flats,athletic field,square,mine,agriculture,and bridges etc.

2. Its outer wall is neat and smooth.Specification is varied from 300mm to 3000mm. According to different usages,the hardness degree of ring is divided into four grades and the max can reach 16kn/m2.It is suitable for the sour alkali liquid below 10%.

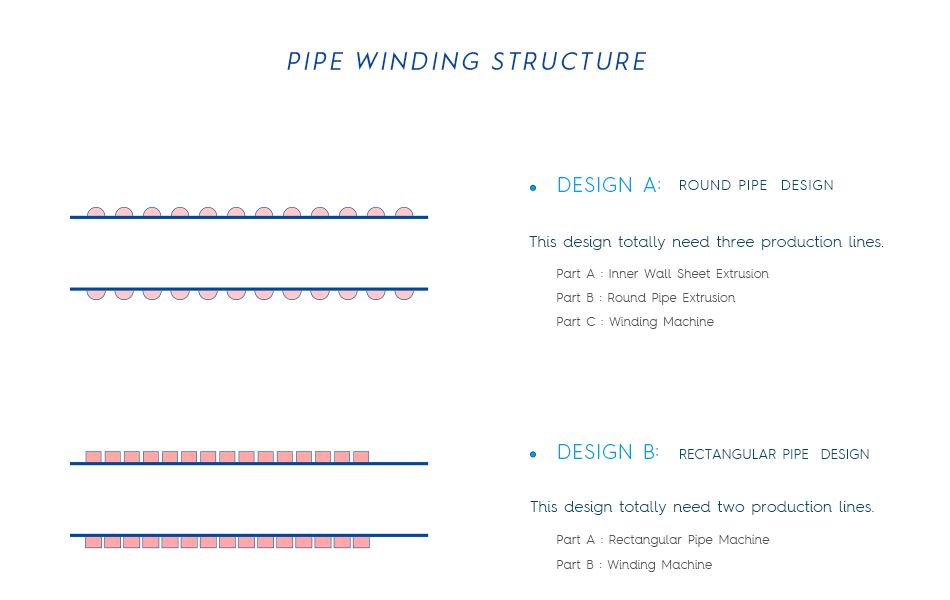

3. High density polythene(PE)is used as main material.The rectangle pipes are extruded by the extruder and then enter into the twine forming machine.At the same time,the second extruder will spray the rubber strips and then squeeze to reunite it.

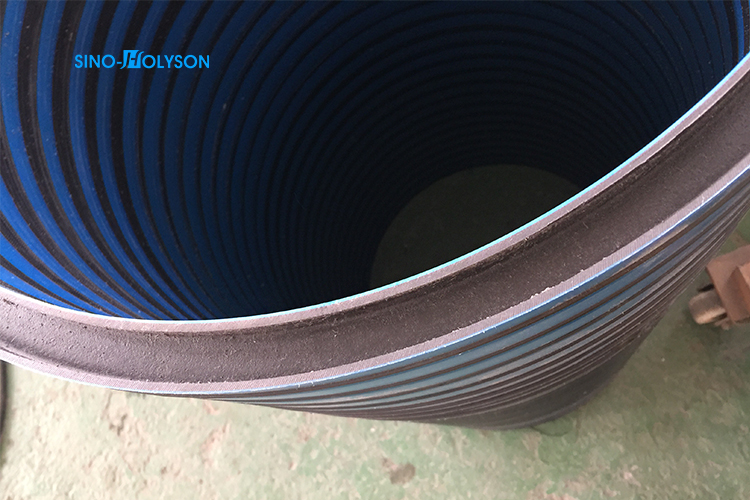

NOTE: RECYCLED + VIRGIN

inner layer black color is Recycled Material, outside layer blue color is Virgin Material.