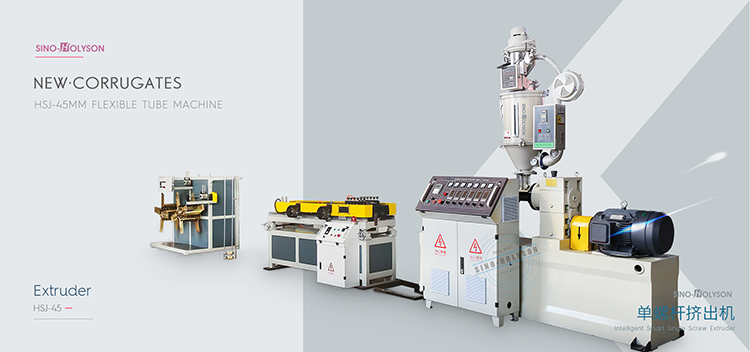

Standard · Flexible Corrugated Pipe Making Machine

Standard Design Flexible Corrugated Pipe Making Machine

HSJ-65 PE Corrugated Pipe Making Machine is mainly designed for the production of PE corrugated pipe. This HDPE Corrugated Pipe machine use a 65mm single screw extruder, installed with 22kw driving motor, which extrusion ability at 35-65kg/hr. The corrugated forming machine is a chain designed, with 72 pairs of mould, running speed is 8~15m/min.

This machine is the most popular choice from different customers, with a reliable performance, easy operation, and better competive price.

Main Machine List:

1. HSJ Series Single Screw Extruder(PP/HDPE | PVC)

2. Extrusion Mould + Die Head

3. Corrugated Forming Machine

4. Double Position Winder(With tension controller)

Single Screw Extruder · HSJ-45mm

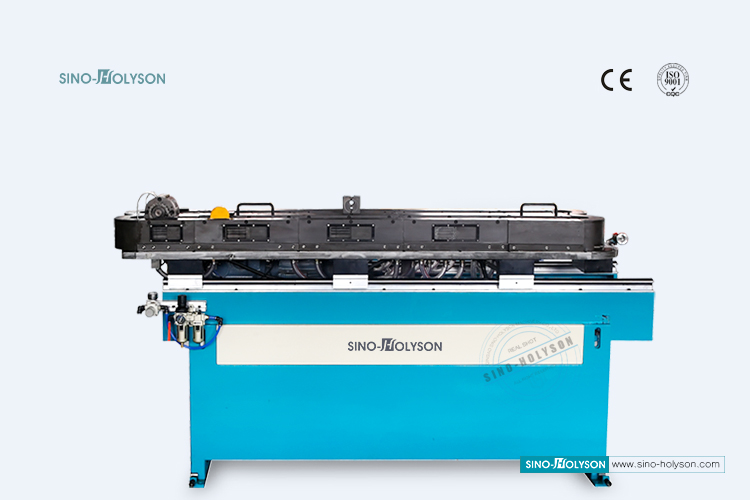

Corrugated Forming Machine

This machine adopts gear transmission module and uses recycled water, forced air for cooling, which production speed can be up to 8-15m/min.The pipe is one-step forming, with uniform shape of the ripples, consistent joint, smooth inside and outside pipe wall. Structure design of special screw and mould is reasonable, replacement of mould is convenient and reliable, and the problem of easy wear of screw barrel and difficult forming of material is solved. The production line has fast and stable speed, easy to operate.

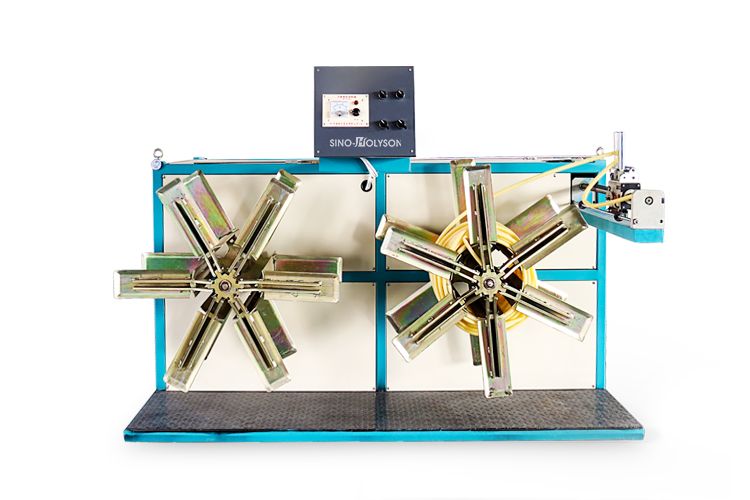

Double Work-Position Winder Unit

This TWO-Position Pipe Winder/Coiler is mainly applicable to wind the corrugated pipe into rolls. It can be used for both HDPE PP/ PVC/ EVA Corrugated Pipes, which directly installed after the the traction machine.

The winder, by using torque motor, promises stable tension controlled. The opening and closing of the winding plate are automatically controlled, which is very easy operation, and maintenance. The winder is equipped with two sets of alternating winding position to guarantee the continuity of production.

Hot Recommend