20-63mm PPR Pipe making machine

φ20-63mm PPR Pipe Making Machine

General Introduction:

This machine is mainly designed for manufacturing HDPE/PP Pipes, which mainly used in irrigation, water supply area. The extruder can process PP/HDPE granules(Both virgin and Recycled, even with chalk-filled composite).

The mounted mould on this line is 20-63mm, full set of mould will include every detailed sized mandrel and sizing sleeve. The whole production line mechanical designing max. 45-80kg/h.

Main Components of a full plant

The following machine units composed one production line.

Only Joecky Extruders are at your optional choice.

| Model | HSJ-65 PPR Pipe Making Machine | Quantity |

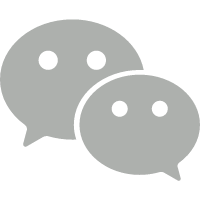

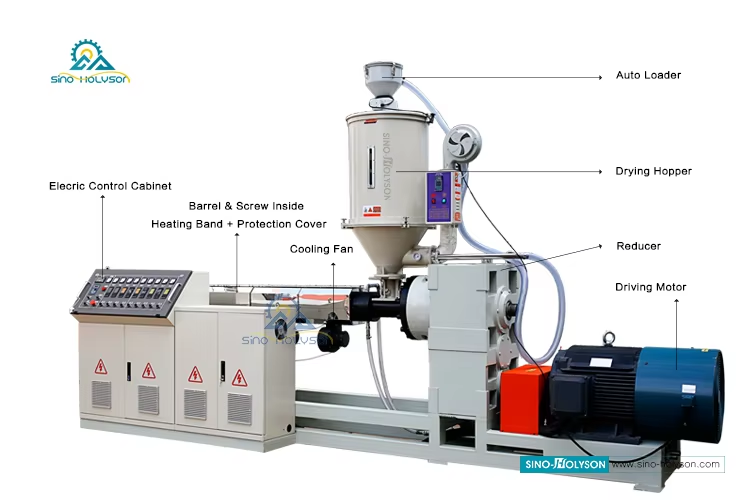

| 1. | HSJ-65 Single Screw Extruder | 1 set |

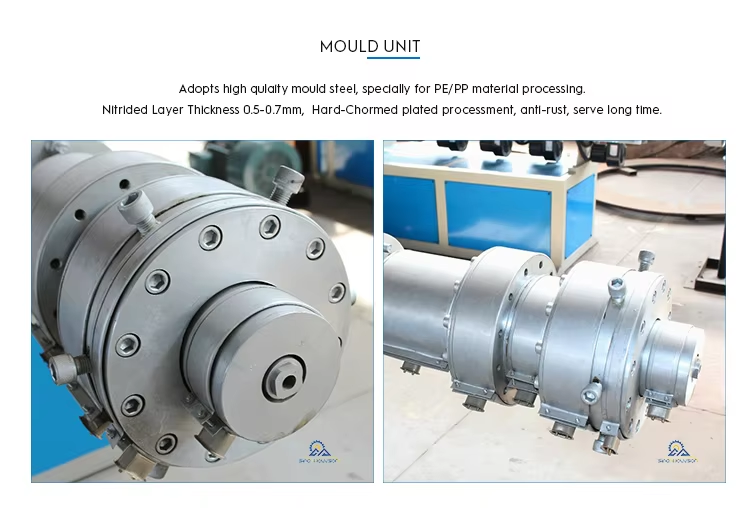

2. | Pipe Mould+Die Head (φ20-63mm) | 1 set |

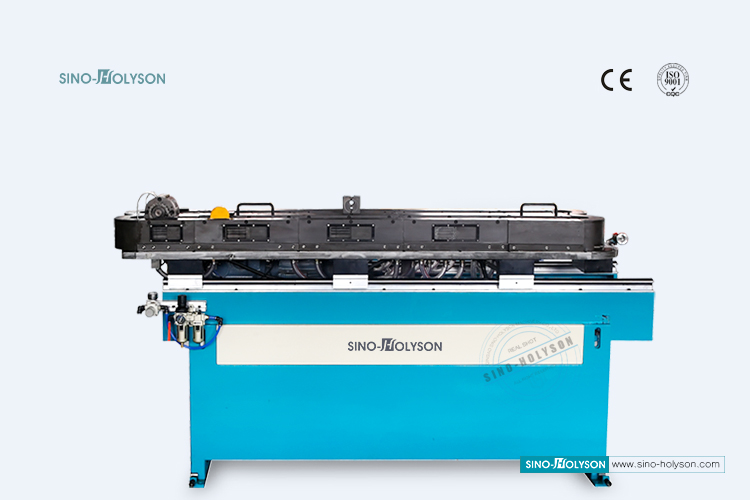

| 3. | Vacuum Sizing Cooling Water Tank | 1 set |

| 4. | Electric Control System | 1 set |

| 5. | Bathing Cooling Water Tank | 2 sets |

| 6. | Double Claw Traction Machine | 1 set |

| 7. | Non-dust Cutting Machine | 1 set |

| 8. | Pipe Stacker | 1 set |

| 9. | HSL-30w Fiber Laser Printer (optional) | 1 set |

Details:

This extruder, which screw model is 65/33, installed with 30kw driving motor, for processing PP/HDPE granules specially. Gear reducer will use from top brand ZLYJ-200 model, with a reliable connection, and higher efficiency distribution, the extruder output can reach upto 50-100kg/h

Mould adopts alloy structural steel, which can greatly improve the strength of the parts. Under high temperature and high load,the mould still has good dimensional stability, ensure the service life of mould and pipe quality.

Fiber laser printers are primarily used for industrial applications that require high-precision printing on metal and other hard surfaces. They

are commonly used for marking, engraving, and etching metal parts, tools, and equipment.

No matter what size of pipe diameter you want to produce, just please confirm with us your requirements, we will provide you with the perfect solution! Feel fee to contact me for any Machine Video and Quotation!