Corrugated Forming Machine Choice

Corrugated Pipe Forming Machine

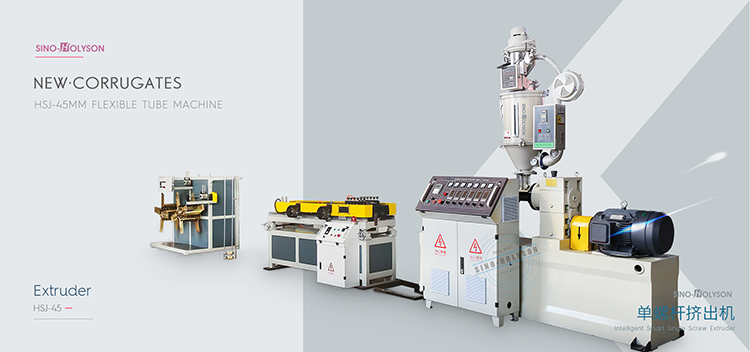

We have two choices for corrugated pipe forming machine. Here let's explain the differences between them each.

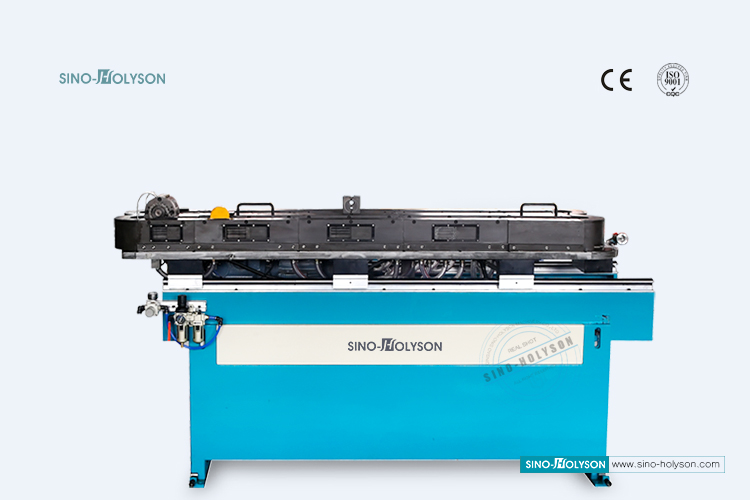

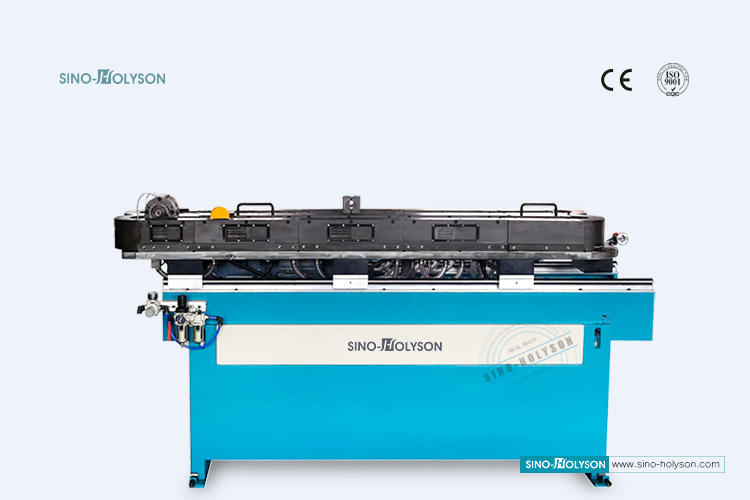

By Standard Machine, the corrugated pairs are chained with each other, driving to go forward by chain. While the higher speed, the pairs are separately arranged inside the trail chamber. But such pairs must be so high accurately processed, any big error will cause pipe diameter change.

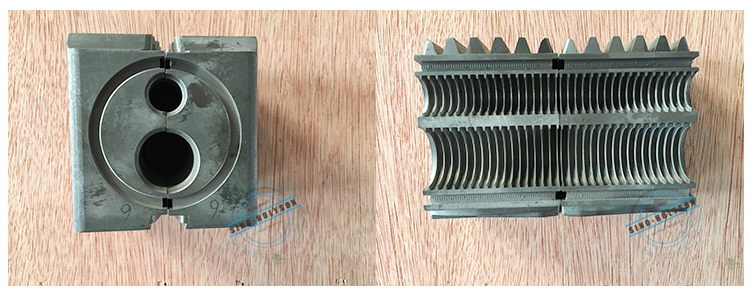

Corrugated Pairs picture is showing in the following picture. Two Cavity is down at the mould. Any size can be made into two cavity, unless is less than 32mm, the most commonly used is 16+32mm, 20+25mm.

Size over 32mm, will be made into single cavity.

Big size, if designed into two cavity, will increase the weight of the forming trail, thus will reduce production speed. While we are designing this machine for higher speed firstly, and single cavity will also guarantee efficiency.

Machine Technical Parameter:

Mould material: Special Nitride Mould Steel

Mould block: 72 Pairs

Forming Specification: 12, 20, 25, 32, 40, 63mm

Max. Haul Off Speed: 30m/min

Motor Power: 4kw

Cooling Type: Cooling Air and Cycled Water

Cooling Power: 0.18kw*2